This reference guide will explain the 3D printing infill pattern to help you better understand the printing process to ensure your part comes out the way you want.

What Is Infill Pattern?

Infill pattern provides internal support for each 3D print layer to form the object. Some 3D printing may not be possible without infill.

Infill patterns also affect the strength or the feel of the final result.

Let’s check out what you need to know below:

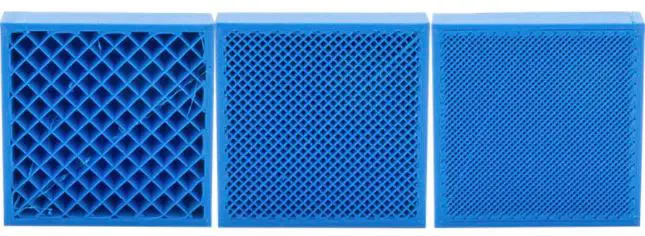

Infill Pattern Types

Let’s classify each infill pattern available for 3D printing processes. Please note, every design is different and it’s important to experiment with them for your design.

Low Strength

Low strength infill pattern is used for parts that aren’t subject to stress or mechanical purposes. Things like scale models and decoration will benefit from this infill type to reduce print time & material usage.

Pro: Fast printing

Con: Low strength

Medium Strength

Medium strength infill is a bit better than low strength for beefing up the object’s structural integrity. It can take a little bit of stress before being totally damaged by heavy stress loads.

High Strength

High strength infill pattern is used in objects made for functional use such as hooks, moving parts, armbar…etc

These parts are designed to withstand moderate stress load, so the infill pattern needs to be solid, in other words, 100% infill.

Flexibility

The infill pattern can give the part some flexibility to serve its mechanical purpose. PLA and ABS plastics exhibit good

Vanity

Vanity pattern doesn’t provide any structural strength to the part, but it takes a longer time to print to add complex shapes and lines to add aesthetics.

Infill Patterns From Slicer Software

Here are some infill patterns offered by common slicer software:

Simplify3D

Cura

Slic3r

Infill Density

Infill density determines the weight and durability of the print. The low-density infill will feel weak even with high strength infill pattern.

Higher infill density will create a heavier and stronger part.

When printing flexible filament, the amount of infill determines how “squishy” the printed part feels. Higher infills with TPU will be more rigid.

When quality is the number 1 priority, higher infill density is recommended and it will take up time, but it’s worth it.

External Infill Patterns

External infill pattern affects the top or bottom layer. External infill pattern allows us to choose rectilinear and concentric.

This mainly affects the finish of the model upon completion.

Key Takeaway

- Lower percentage infill for display object

- Higher percentage infill or 100% infill for mechanical parts made to endure stress load

FAQ

What’s The Strongest Infill Pattern?

The strongest infill pattern is 100% infill because it’s solid form without any hollow area.

Infill Percentage VS Strength – Which To Pay Attention To?

What Causes Weak Infill?

Higher printing speed will cause under extrusion, and it tends to create weaker infill.

How Strong Is 50% Infill?

50% infill is recommended for functional parts that are designed to withstand stress. Even 100% infill is recommended for making strong parts.

How Strong Is 20% Infill?

20% infill is strong for non-functional parts that aren’t designed to withstand stress load. It’s recommended for prototype or display model